The QuietKit ™ began as an internal challenge at dbsorb. The team wanted to find a higher-value use for sheet offcuts, giving them a third life before of sending them to recycle. The outcome was a modular frame-and-panel system that delivers studio-grade acoustics, installs with simple tools, and can be rearranged at any time.

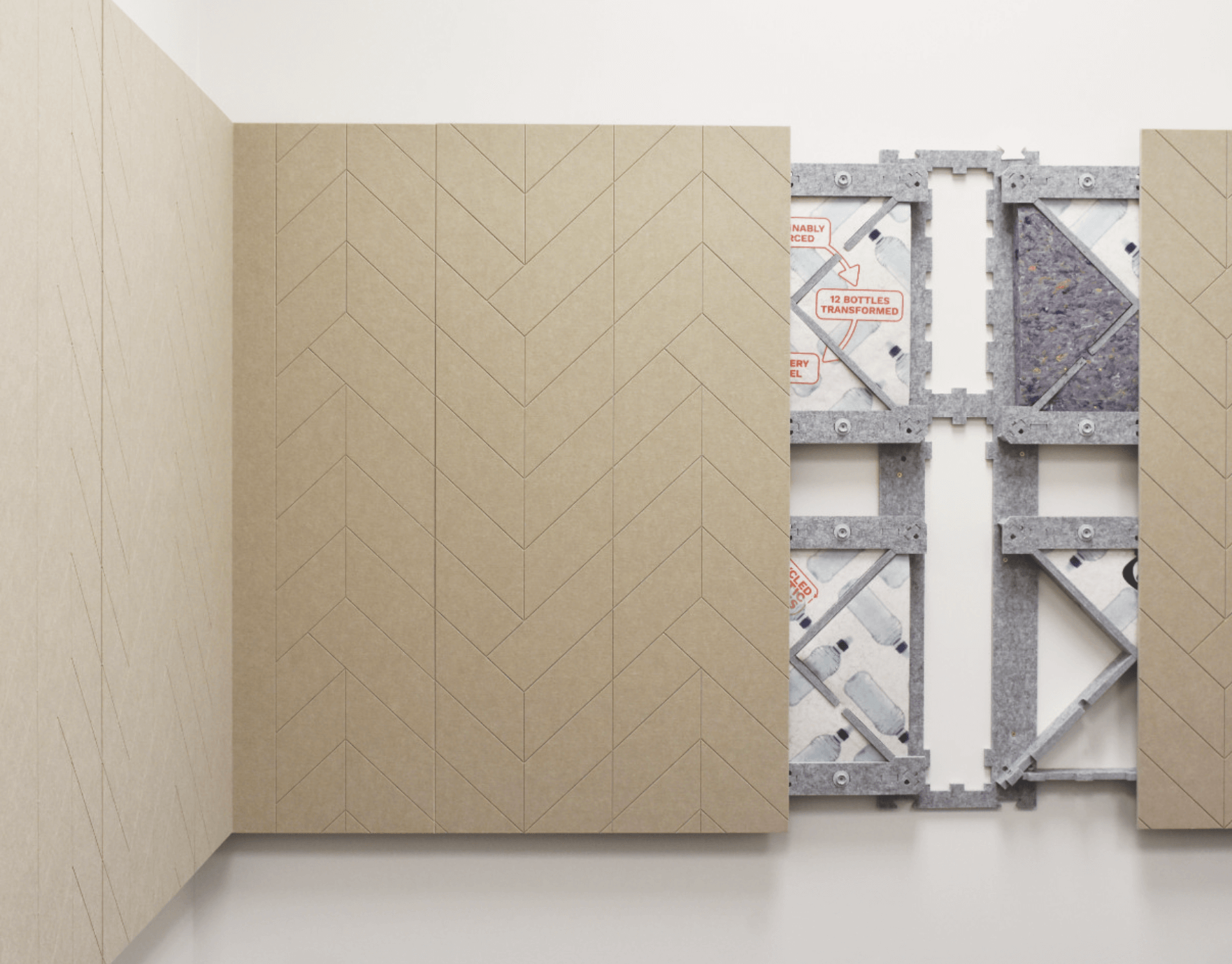

Every QuietKit ™ frame is made from factory offcuts and fixed to the wall with dbsorb’s mechanical clip system. The design also allows for optional low-frequency absorption infill made entirely from off-production offcuts, as well as interchangeable whiteboard panel modules. Acoustic panels clip directly onto the frame, ready to be changed or repositioned without tools.

This approach keeps waste out of landfill, avoids adhesives and VOCs, and creates a product that is endlessly reusable. Vertical or horizontal. Longer or shorter spans. The QuietKit ™ is built for change.

Meeting Luke’s unique studio needs

When Luke Kemeys approached dbsorb, he had a specific challenge. He was launching two different podcasts from the same room: The Next Advisory Podcast for his accounting firm, and Keep The Change Podcast, aimed at improving financial literacy across New Zealand. He wanted the flexibility to switch visual branding between recordings, while keeping the sound quality at a professional level.

The QuietKit ™ was a perfect fit. dbsorb customised the acoustic panels with printed branding for each podcast. Panels could be unclipped and swapped, instantly changing the studio backdrop to match the show being recorded.

How it comes together

The QuietKit ™ system was factory-finished for a fast and clean installation. The frame was fixed in place, then the branded acoustic panels were clipped on. Luke can now swap panels with ease, even joking that “an accountant like me can figure it out” despite not being a DIY expert.

The flexibility of the system means the studio can evolve over time. Luke could introduce new branding, insert low-frequency absorption infill into the frame cavities (made entirely from off-production offcuts) for deeper sound control, add optional whiteboard panels for planning sessions, or adjust the layout without damaging the walls. No glue. No mess. No waste.

Why reuse is more sustainable than recycling

dbsorb takes a full-lifecycle view of sustainability. Traditional glued acoustic linings often damage the wall when removed, leaving torn surfaces and generating contaminated waste that cannot be recycled. That waste is costly to repair and ends up in landfill.

Damage left behind after removing glued acoustic linings — exactly the kind of waste, mess, and unnecessary repairs DBSORB’s reusable systems are designed to eliminate.

By avoiding adhesives entirely, the QuietKit ™ prevents this damage and waste. Every frame in Luke’s studio came from material offcuts, showing how discarded material can be turned into high-performance acoustic solutions. This approach aligns with dbsorb's mission to help reduce the building sector’s environmental impact, which contributes nearly 40 percent of global emissions.

Luke’s feedback

“One of the problems we were hoping dbsorb could solve was that we could interchange panels so we could run multiple podcasts out of here. That is exactly what the team at dbsorb have been able to do for us. Even an accountant like me can figure it out. I'm not very good at DIY, but that's pretty easy.”

“The dbsorb team helped me create a bespoke podcast studio using their custom technology. There is nothing else like it in NZ. Super thorough, patient, and an impressive process start to finish.”

A studio built for change

Luke’s podcasts reach thousands of listeners each month, delivering clear, practical business and finance insights. With the QuietKit ™, he now has a space that matches his content: professional, adaptable, and ready for whatever comes next.

For dbsorb, it is a practical example of how R&D, sustainability, and client needs can align to create something that works today and will keep working far into the future.

Skip to content

Skip to content